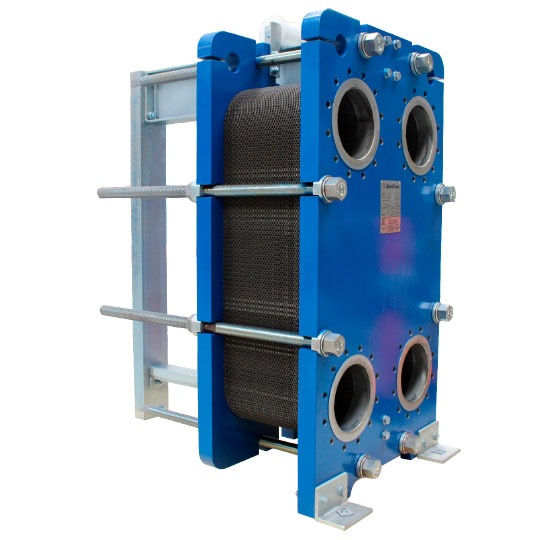

SonFlow Plate Heat Exchangers

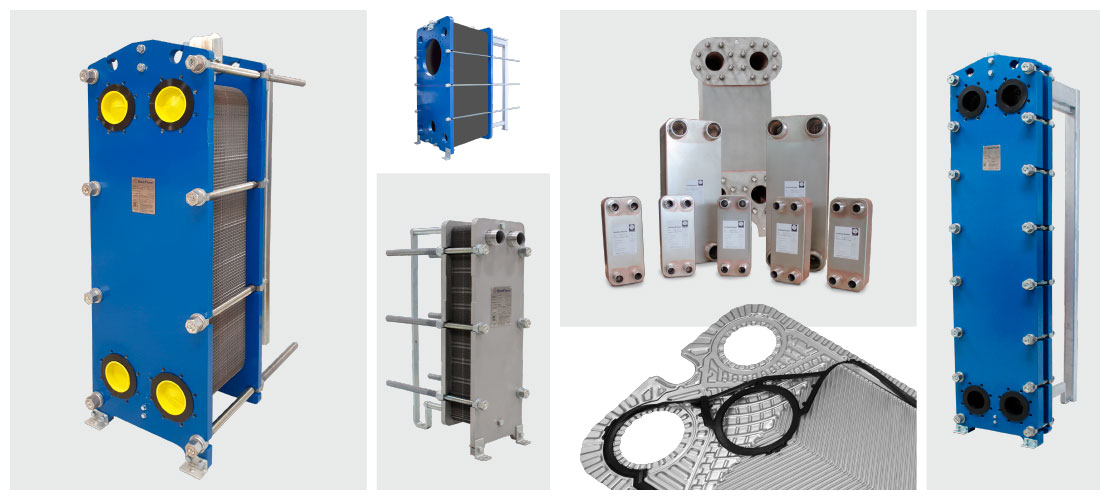

SonFlow has developed an optimized and efficient range of plate heat exchangers, based on more than 45 years of experience. Our product line includes traditional, free flow, sanitary, condenser/evaporator, and brazed plate heat exchangers.

All our plate heat exchangers are customized to meet specific temperature requirements and capacities. this ensures that you will receive a plate heat exchanger tailored to your needs, regardless of the industry or process you are working with.

SonFlow benefits

- Founded by Aage Søndergaard, with decades of expertise in plate heat exchanger development.

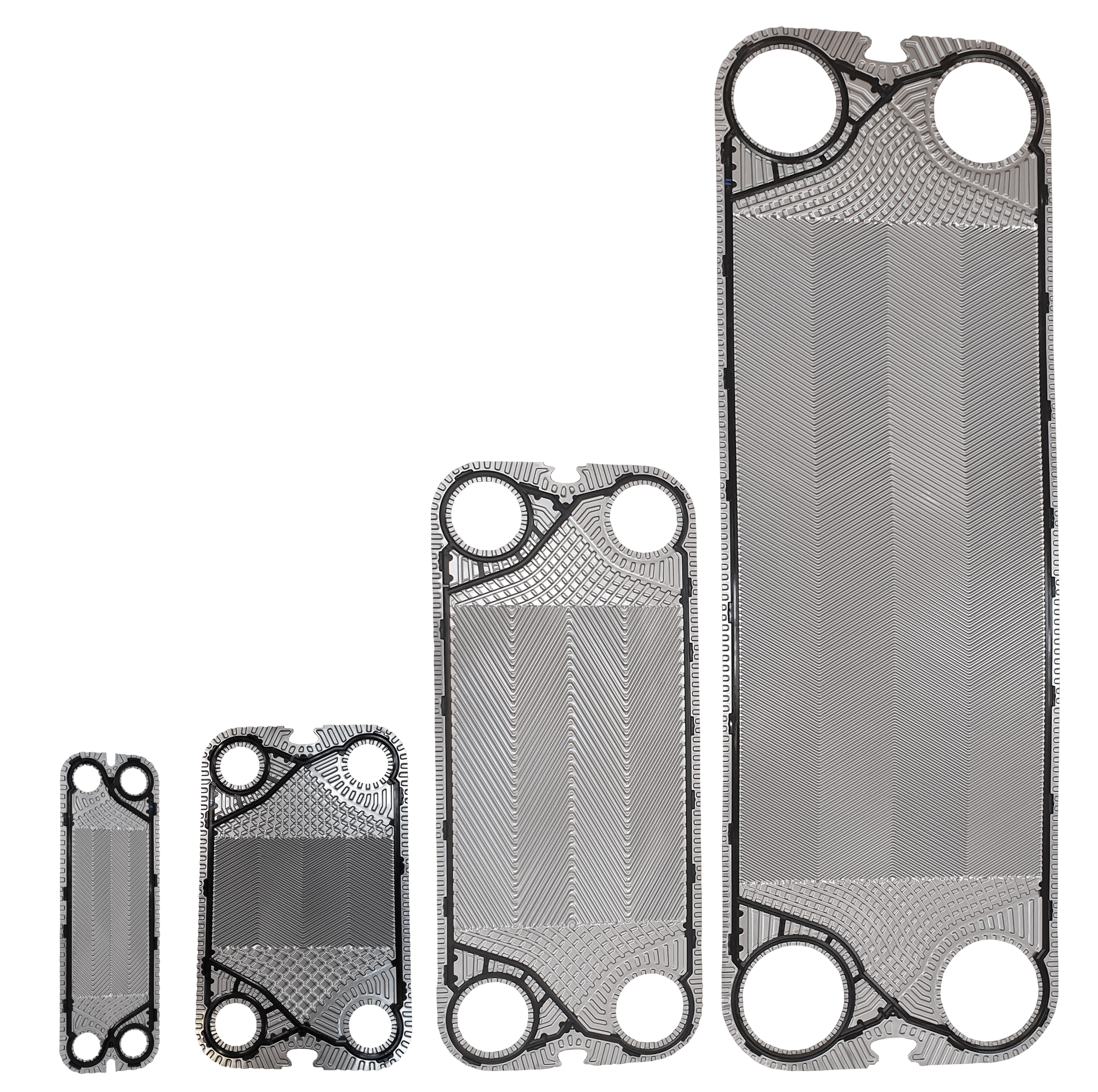

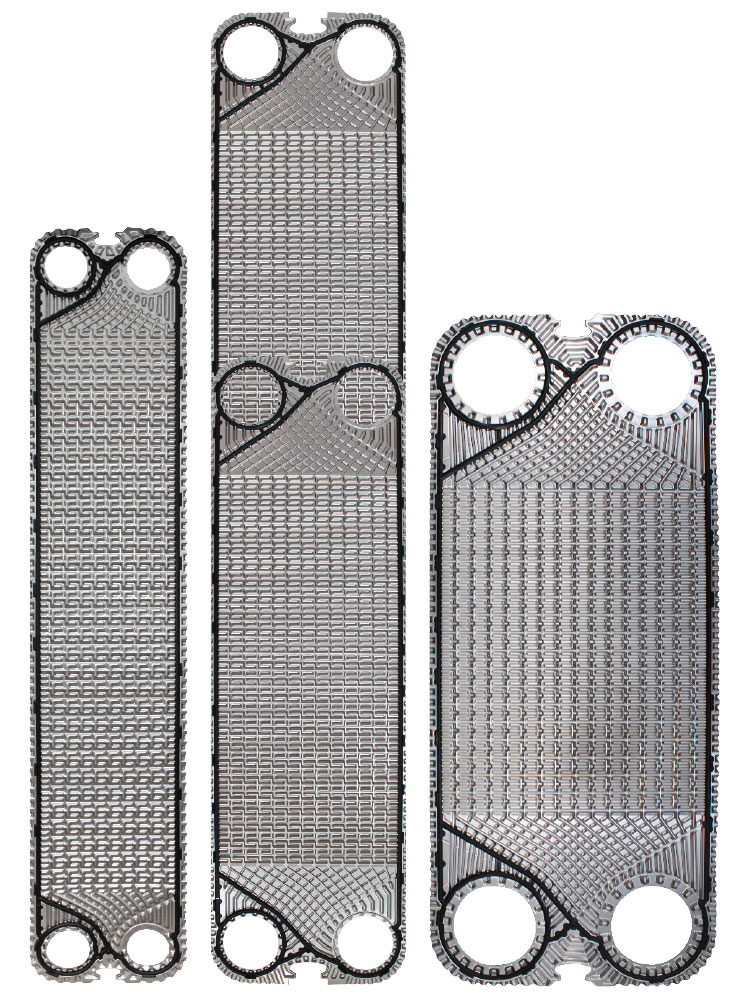

- Offering a wide range of plate types.

- Engineered to match real-world operational demands.

- Aimed to optimize efficiency and minimize energy consumption.

Advantages of SonFlow Plate Heat Exchangers

Expandable

Saves time and money.

Compact Size

High Efficiency

Due to pressed patterns in the plates and the relatively narrow gaps, very high turbulence is achieved at relatively low fluid velocity.

Close Approach Temperature

Possible to achieve close approach temperatures.

Multiple Duties in a Single Unit

Can be constructed with multiple sections, separated by divider plates or more complex divider frames.

Less Fouling

A smooth plate surface minimizes fouling.

Lower Costs

Easy to Clean

Remove the tie bolts and slide back the moveable frame part, the plate pack can be easily inspected and cleaned.

SonFlow provides a comprehensive range of sustainable plate heat exchangers suitable for various industries:

Applications:

SonFlow plate heat exchangers are solving heat transfer process challenges in many different industries:

- HVAC

- Marine

- Industrial

- Sanitary

- Wastewater

- Sugar

- Biogas

- Pulp and paper

- Mining

- Chemical

- Alcohol

- Oil and gas

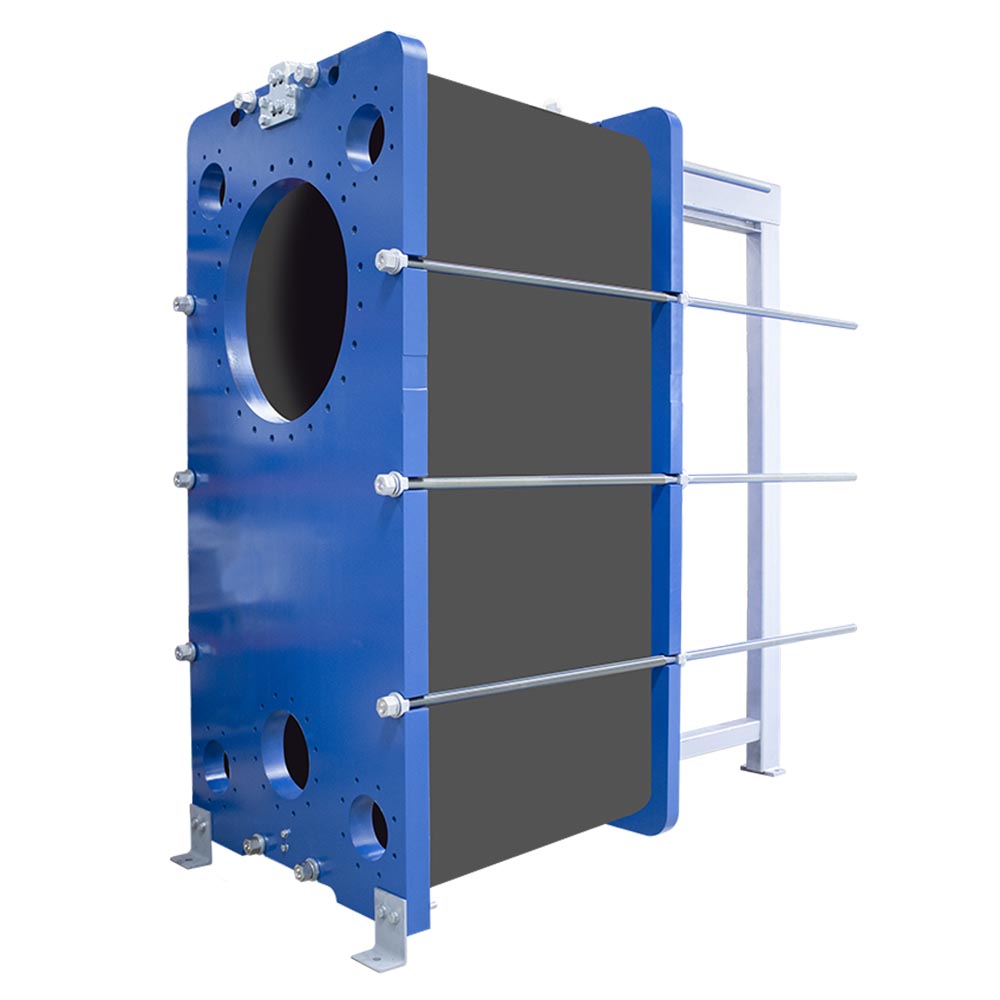

Frame Construction

SonFlow’s plate heat exchangers are constructed to be extremely sturdy and with a robust structure. We offer different frame designs depending on the task and size of the plate heat exchanger.

Our frames are designed to provide easy access for

inspection, maintenance, and cleaning, including CIP-cleaning. With our frames, these tasks can be carried out smoothly and quickly, minimizing downtime and

increasing productivity.

We are ready to assist you

No matter what challenge you are facing, we are always ready to advise you on the best solution within pumps and plate heat exchangers.

Feel free to call us +61 (3) 9754 2852

Dansk

Dansk Australia

Australia Deutsch

Deutsch