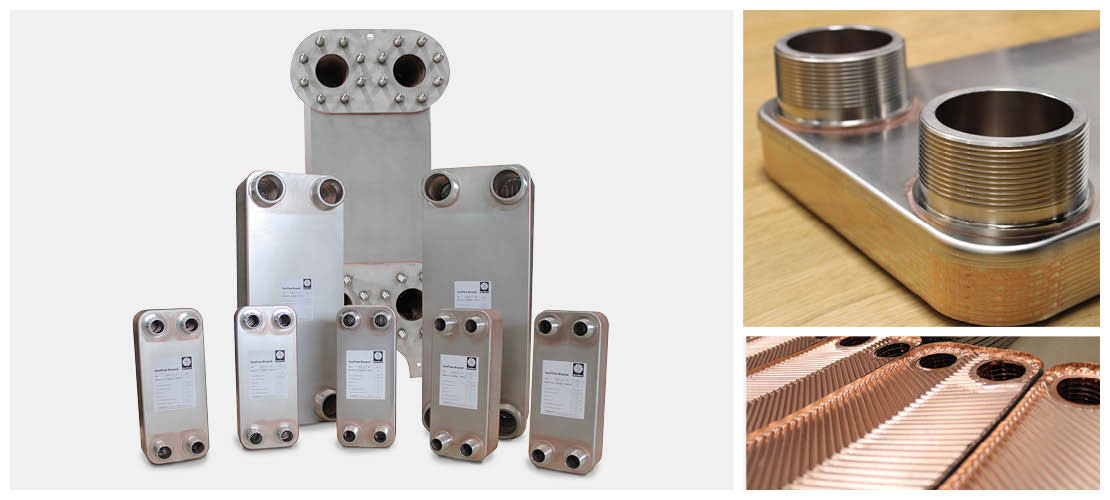

Permanently Sealed Brazed Heat Exchangers

SonFlow’s new efficient brazed heat exchangers (SFB) are permanently sealed heat exchangers suitable for a wide variety of applications across numerous market segments.

For the brazed heat exchanger series, the key focus lies in reliability and high performance. Our talented team with more than 40 years of experience in heat exchangers has developed and thoroughly tested the efficient brazed heat exchangers, handling advanced heat transfer technology.

Features

Every detail is carefully designed to ensure optimal performance, reduce maintenance costs, and decrease downtime.

One of our focus areas is sustainability and therefore it is important that the units are energy-efficient and environmentally friendly.

Construction

The Brazed heat exchanger is constructed by a package of thin corrugated metal plates, surrounded by two thicker stabilizing plates. A thin copper foil placed between each of the thin metal plates melts and seals the brazed plate heat exchanger during a vacuum brazing process.

We calculate each solution based on the customer’s requirements to ensure an ideal pressure drop and flow rate. And at the same time, the unit becomes energy-efficient and environmentally friendly. Based on the individual task, we also determine the number of plates and the size of the brazed heat exchangers.

Plates

The design of the corrugated plates optimizes heat transfer by providing a large but compact total surface area whereby the heat can be drawn from one liquid or gas to another.

The plates are optimised to meet specific temperature demands and capacities.

Designed to meet your needs

Our extensive range ensures that we can offer the best solution at the best price and, if required, combine several different types of heat exchangers to ensure that you get the best possible solution.

Technical specifications:

- Plate material: AISI 316

- Brazing material: Copper

- Design pressure: 25 and 40 bar (362 and 580 PSI)

- Temperature: -100 to 185˚C (-148 to 365˚F)

- Connections: between ¾” and DN100

Industries:

The compact brazed heat exchangers can be used in nearly all areas of heating and cooling processes, including:

- General cooling/heating

- HVAC

- Refrigeration

- Industrial

- Marine

- Data centres

- Heat pump

- Solar heating

BPHE Benefits:

- Lower operating costs

- Cost-effective

- Easy assembly

- Increased energy efficiency

- Low weight

- Compact design

- High flexibility

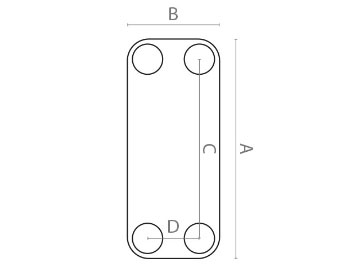

Brazed Heat Exchangers Overview

| A | B | C | D | |

| SFB21 | 291 | 114 | 242 | 65 |

| SFB31 | 305 | 128 | 242 | 65 |

| SFB32 | 509 | 128 | 446 | 65 |

| SFB51 | 618 | 191 | 519 | 92 |

| SFB61 | 617 | 247 | 520 | 150 |

| SFB81 | 747 | 329 | 623 | 205 |

| SFB101 | 1004 | 381 | 862 | 239 |

Measurements are in mm

Feel free to call us +61 (3) 9754 2852

Industries

Specifications

Cleaning and maintenance

All our plate heat exchangers are designed with a focus on providing easy access for quick and hassle-free inspection, maintenance and cleaning.

- The plates in our brazed plate heat exchangers are made from stainless steel, ensuring they are easy to clean.

- The heat exchanger supports CIP-cleaning (Cleaning in Place), allowing it to be cleaned directly within the system without requiring disassembly or relocation. This feature simplifies post-use cleaning, ensuring that your system remains free from contamination in the next production cycle.

Find our guide for CIP-cleaning our Brazed Heat Exchangers here

Product Overview - Brazed Plate Heat Exchanger

We are ready to assist you

No matter what challenge you are facing, we are always ready to advise you on the best solution for pumps and plate heat exchangers.

Feel free to call us +61 (3) 9754 2852

Dansk

Dansk Australia

Australia Deutsch

Deutsch