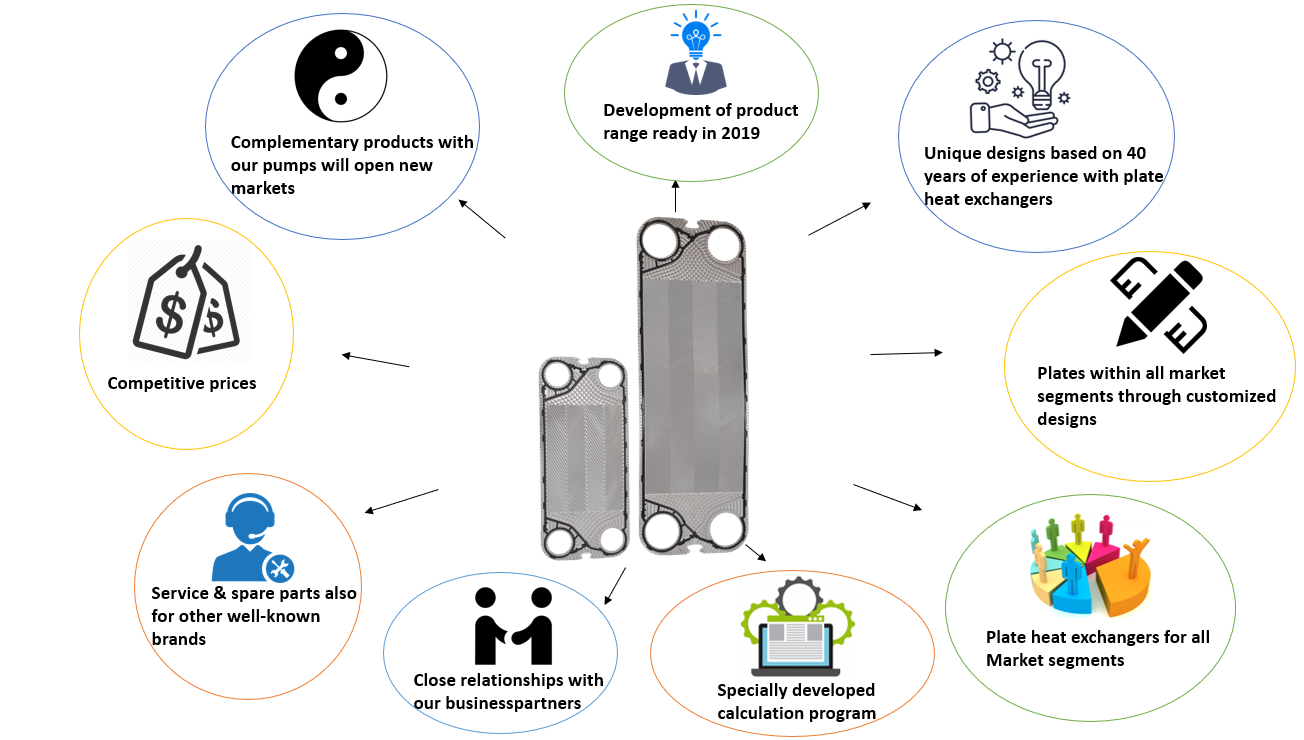

Product range:

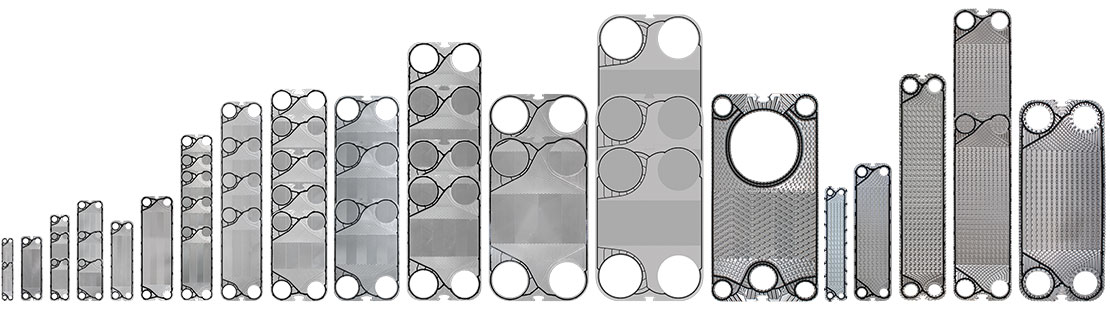

SonFlow offers a wide range of gasketed plate heat exchanger that boosts sustainability with an energy-efficient design. Compact frame and innovative plate patterns.

Suitable for all types of industry and multiple applications from heating, cooling and heat recovery to condensation and evaporation.

We are constantly looking to extend and upgrade the range, adding new performance criteria and greater flexibility.

The design of the corrugated plates optimizes heat transfer by providing a large but compact total surface area through which the heat can be drawn from one liquid or gas to another.

The heat transfer area of the plates is pressed in a corrugated herringbone pattern. Our patterns create the ideal turbulent flow and make the best use of the available pressure drop for any duty.

An optimized flow distribution also reduces fouling and uneven temperature zones keeping the performance levels high over time without unnecessary energy losses, maintenance costs or unplanned stops.

Plates are available with various pressing depths, angles of chevron pattern and various corrugation shapes, all carefully designed and selected to achieve optimal performance - depending on the application, each product range has its own specific plate features.

Applications

- HVAC industry - e.g. district cooling solutions using seawater and groundwater as cooling source - e.g. district heating solutions using, for example, solar and geothermal energy as heating source

- Marine/offshore industry - e.g. central and lubrication oil cooling

- Dairy/food/beverage industry - e.g. pasteurization, heat recoveries, and duties that require gentle treatment

- Sugar industry

- Biogas industry

- Pulp and paper industry

- Heavy industry

- Mining industry

- Petrochemical industry

- Chemical industry - e.g. waste heat recovery from condenser water

Technical specifications

- Connections from DN25 to DN400

- (Frames designed according to PED 2014/68/EU (EN13445) and ASME sec VIII, Div. 1 construction standards)

- Plate materials: AISI 304/316, titanium, SMO. Other materials available upon request

- Gasket materials: EPDM, NBR and Viton.

- Plate heights up to 3.5 m

- Flow rates up to 7200 m³/t (31,700 gpm)

- Working pressure up to 25 bar (363 psi)

Special SonFlow benefits:

- A short pay-back period on investment.

- High thermal efficiency due to knowledge, experience and the design

- Compact design and simple installation

- Each heat exchanger is individually designed for the heat load, flow

rate and pressure drop limitations of the specific application. - Energy efficiency solutions has the power to protect the environment and create greener solutions.

Dansk

Dansk Australia

Australia Deutsch

Deutsch