Wastewater pumps S-WP

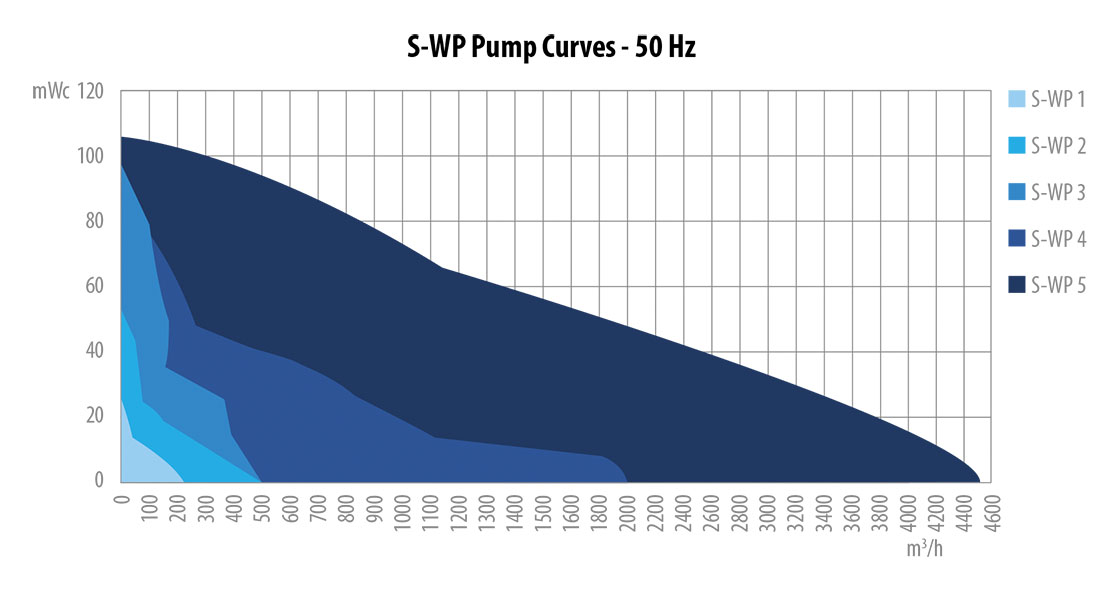

The Danpumps S-WP pump: With the range of submersible pumps from the small S-WP1 to the big S-WP5, we cover the need from light industrial effluents to heavy duty wastewater jobs from both cities and industries. The flowrate varies from 68m³/h to 4000 m³/h, and we have connections from DN50 to DN600.

The S-WP pumps can be used in many different applications by adjusting motor size and impeller type, the solution can easily be customized to comply with your requirements.

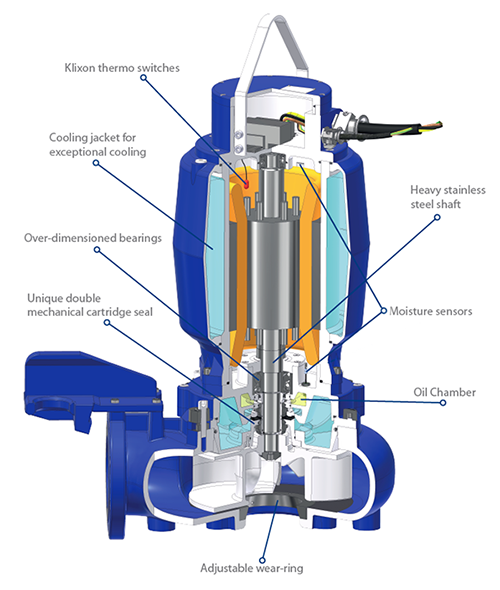

The design of the S-WP pump is a combination between high efficiency, intelligent design and practical features.

The efficiency of the pump is very important to be able to reduce running costs of the pump and in the same time reduce the CO2 release to the environment, and this is achieved by the design of the impeller and use of high-efficient IE3 motors. It gives you a user-friendly pump with a long-life cycle which will reduce maintenance costs.

Features

- Different types of impellers fit in the same volute

- Cartridge seal

- High-efficiency IE3 Premium motors from Siemens with klixon thermo switches

- Moisture sensors

- Unique motor cooling system

- Maximum temperature of liquids: 45°C

- Designed for easy maintenance

- Offer frequency converter

Industries

Specifications

When choosing the impeller

The choice of impellers depends on the nature of particles in the fluid. Designed to fit in the same volute and customized according to customers demand.

By optimizing the impeller, we make sure to hit the wished duty point and thereby saving energy consumption.

Can be delivered in cast iron, stainless steel and duplex as an option.

Choose the most optimal impeller:

- One or two channel impeller

- High efficiency (70-80%) however some possibility of clogging

- B-tween impeller

- Less efficient (60-75%) than the channel impeller, but lower possibility of clogging

- Vortex impeller

- Less efficient (30-40%), but it is clogging free due to free passage, therefore it is reliable

Cutter impeller

A cutter impeller for the S-WP and S-WN wastewater pump specially designed to handle solids. The impeller has sharp edged scissor like vanes with blades designed to grind any solids before they enter the pump.

- Non-clogging impeller

- Cutting action for your toughest challenges

- Multi-vanes design for the highest possible efficiency

The cutter impeller is perfect for pumping heavy wastewater/sewage and is designed for providing excellent cutting mechanism to shred diapers, sanitary pads, rags, plastic bags, sludge and fish silage in residential, commercial and aqua cultural applications.

The impeller is made of AISI 316, and the blades are made of hardened tool steel to overcome heavy-duty challenges.

Cartridge seal

A user-friendly cartridge seal that makes it possible to change the seal without using any special tools or personal with specific skills, which eliminates any risk of improper installation.

The cartridge seal has built in an impeller for circulation of motor cooling fluid. The cartridge seal is pressure tested before shipment and ready for assembling.

Double seals are generally used with unstable, lightly toxic, abrasive, corrosive and viscous fluids.

How to replace the cartridge seal:

- Tap oil

- Loosen latch bolts

- Tap cooling water from the cooling jacket

- Remove impeller

- 4 bolts for release

- 2 pull threads

We have done the work for you – all-in-one to provide simple sealing solution and ease of installation. The service time of the seal is reduced compared to a normal double mechanical seal.

Volute

The casing is the major stationary component of the pump and mainly provides two functions:

- Converting velocity head from the impeller into pressure head and guidance of the flow to the discharge connection

- Creating a pressure boundary for the pumped liquid

A volute is a spiral-like form such that as the liquid is discharged from the impeller into the volute casing, the volute areas increase at a rate proportional to the discharge of liquid from the impeller and a constant velocity exists around the periphery of the impeller.

High efficiency motor from Siemens

The S-WP pump is equipped with a Siemens IP68 motor IE3. The Siemens motor has an efficiency up to 95,8%. The motor is protected by the thermo klixon from getting overheated together with moisture sensor.

In dry installations, the motor is protected by the cooling jacket.

Siemens Premium IE3 motor gives a significant cost reduction and saves energy compared to the IE2 motor. The IE3 Premium motor from Siemens achieves a higher efficiency and a cost benefit of 20-45%.

IE3 efficiency is up to 95.8%

Fast lock latch bolts

To separate the pump very easily from the motor when doing service.

The pump will be separated thus the rest of the pump is lifted up without affecting the pipework.

This feature is very popular with the service staff, as it reduces to

maintenance downtime considerably.

The locks are made in stainless steel.

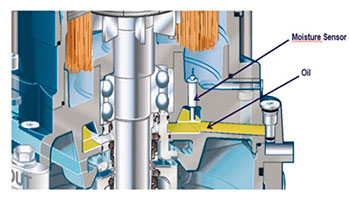

Oil tap drain

It is important to tap the oil. It is also important to tap the water from the cooling jacket before taking out the cartridge seal.

The pumps are equipped with oil tap drain making service and oil change very easy.

Thermo klixon

A standard protection in all our motors for the S-WP pump range.

Thermo switches disconnect the power at the temperature of 150° C this ensures that overheating will be avoided.

Cooling jacket

The closed cooling jacket is standard for the Dry Pit and Portable Pit pumps and can be supplied as an option for the Wet Pit pumps.

This cooling system ensures an optional cooling of the motor, which avoids the risk of overheating. The pump is cooled by the internal media that circulates by the impeller in the cartridge seal, which transfers the heat to the the bottom plate.

Moisture sensor

Is another standard protection in our S-WP pumps.

The moisture sensor measures if there is water in the oil and also if there is water in the stator house. Attached to a control panel an alarm will sound, when the moisture level is too high then the pump will stop automatically.

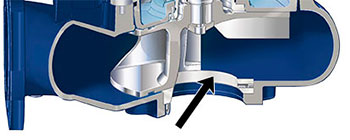

Adjustable wear-ring

DanPumps pumps uses an axially adjustable wear-ring to reduce the hydraulic loss between the impeller and the wear-ring.

By this feature the wear-ring can regularly be adjusted to optimize the pumps efficiency when the pump starts to be affected by wear.

Submersible pump cables

H07RN-F cable

- Tough & flexible cable

- Excellent moisture, abrasion & weather resistance

- Safe, reliable and power saving

- Available in 10m

As an option: RS PRO SY screened cable for the frequency converter

Dry, wet & portable wastewater pumps

The DanPumps S-WP product program is delivered for dry, wet or portable installations with the choice of a vortex, a B-tween or a channel impeller.

As an option, all DanPumps dry pit wastewater pumps can be delivered as a S-WN pump with an IEC standard motor →

see S-WN pumps

Dry pit

- Vertical, permanent, dry installation with flange connection to suction and discharge piping.

- Safe if flooding occurs

- No visible rotating parts

- Easy to install and retro-fit

- Adjustable legs

- Good environment

- Cooling jacket

Wet pit

- Semi-permanent, submersible pump installation on twin guide bars with automatic connection to the discharge pipe

- Connects directly to another installation by adapter

- Flange to flange connection is by metal to metal contact → simplicity

- Interchangeable and connects directly to other pumps

- Without cooling jacket

Portable pit

- Portable, submersible pump installation connected to discharge pipe.

- Easy to install

- Adaptable base ring-fits 3’’, 4’’ and 6’’ suction flange drillings

- Base ring is shock resistant

- One pump multiple location

- 90° flange hose connection

- Cooling jacket

S-WP Pump curves - 50 Hz

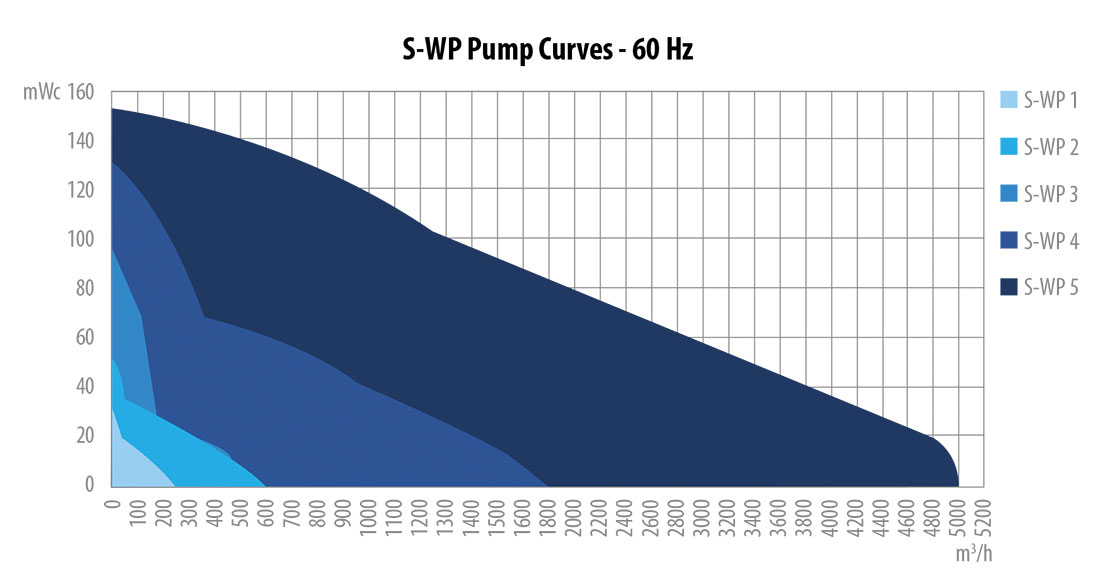

S-WP Pump curves - 60 Hz

Dansk

Dansk Australia

Australia Deutsch

Deutsch